3d Pritner (X, Y, Z) Automatic Calibration (1)

- Dr. Tõnis

- Oct 4, 2019

- 2 min read

At the moment the FDM 3d printing industry is moving towards 2 print head system, or it is already there. The main issue with this approach is the calibration. The fully automatic bed calibration technology is already in the market, however something like that for X-, Y- and Z-axes does not exist or at least in the moment of writing I was not aware of it.

I am Dr. Tõnis and I worked till the end of 2018 in a startup developing our own high end 3d printer (the main competitors were Ultimaker 5S, Leapfrog Bolt and Raise3D Pro2). Our team was small and I was responsible for the electronics and software (PCB design, component selection, user interface software, firmware, etc.). After some financial difficulties the management decided to close to company. It is a pity as the printer was almost ready and I really enjoyed the work.

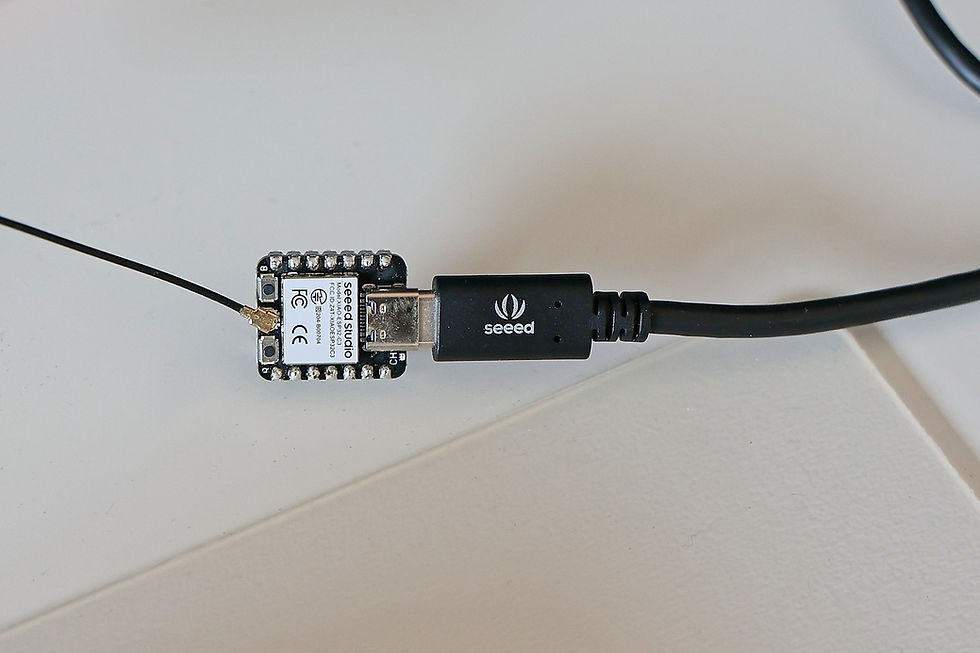

During the fully automatic bed leveling system implementation, I had an idea how I could build a fully automated X-, Y- and Z-axis calibration system. The prototype is an external device that is attached to the printer before the calibration process and after the calibration is done the device has to be removed. The idea is in an early stage prototype and needs further testing and improvements. Nevertheless, the hardware of the calibration device is very cheap and would cost less than 10$ (only the measuring device, controller not included).

Since I was not able to realize the idea I’m publishing here the concept. At the same time I am explaining relatively thoroughly how a dual head 3d printer calibration is done.

Our developed printer printhead construction was very close to BCN Sigma design, thus the following discussion explains how BCN does the calibration. And how the automatic device could be used with their printer, however the same principles apply to all other printers. For example, with Ultimaker only the T0 Z calibration could not be done very precisely by using this method, all other calibrations could be done without changing anything. If we know that the calibration device is always (let say) 11.2mm thick then one can use that for Ultimaker T0 Z calibration, nevertheless most probably a fine tuning would be needed.

I assume the device could be used even with a CNC machine, although with several limitations. In the CNC machine the Z calibration is a critical component and that could be easily done with this calibration device. However, I do not have much experience with a CNC machine, thus my assumption could be wrong.

The prototype has been partially tested and for the Z axes it works well (limitations mentioned later in the Known issues chapter). The X axes has been tested too and there theoretical accuracy of 0.05mm has been achieved. Testing has been successful, nevertheless some more work would be needed.

Comments