Flip-Dot display prototype

- Dr. Tõnis

- Mar 3, 2025

- 2 min read

11.2024 – 02.2025 (3 months)

Description

Having seen some very attractive flip display projects online I wanted something similar. After some research I found the company who is behind them, however the price was out of my reach, thus I decided to try to build my own version of it. https://flipdots.com/en/home/

Project summary

In this project I tried to find simple possibilities to build the flip dots. The mentioned company uses small electromagnetic coils and building them would be way too much effort for me. Therefore I needed alternatives. In the end I thought about using a PCB electromagnet together with a magnet.

My responsibilities

Alternatives for electromagnets definieren

PCB and CAD design for the whole flip-dot operation

Testing and building

Results

The project started with CAD modelling. This project has few challenges. First I wanted to have as small flip-dots as possible. Secondly, I wanted to use a 3d printer for cheap construction. The last one was defining the minimum dot size. Therefore I had to redo the CAD model several times, additionally it required several iterations till it looked printable. After some test prints I decided that it could work and started with the PCB design. The final prototype dot was 10 mm in diameter.

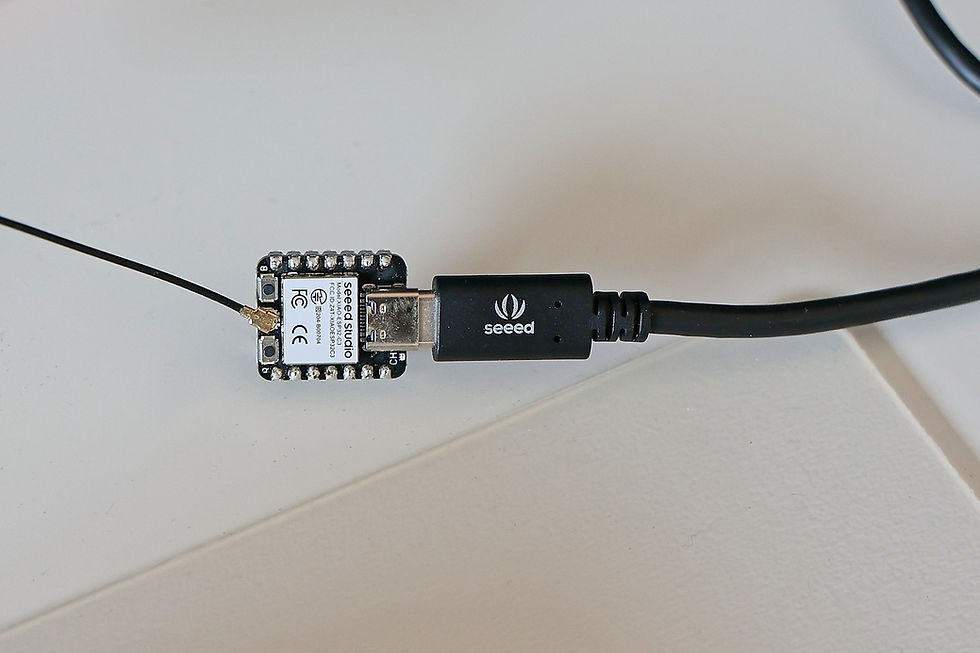

Designing a PCB coil took some time, however in the end I was happy with the result. Since everything was so small I had to use 1.27mm pitch headers. I'm sure that it would have been a headache to plug a driver PCB (would have been a second part of the project) to turn the coils ON and OFF. I proceeded anyway and ordered the PCB to test out the prototype.

After receiving the PCBs I printed everything needed and started testing. Unfortunately the electromagnet was not strong enough to flip my dots. The second and probably even larger issue was that the dot magnets were too close and affected each other. Thus, I needed larger dimensions and to start from zero again. Nevertheless, I decided to stop here. Due to the fact that my electromagnet was way too weak to slightly affect the dots it didn't make sense to try with a larger unit.

I think the idea was good, unfortunately this time it didn't work as hoped.

Used tools

SW: Fusion 360, EasyEDA

HW: 3d printer, magents, soldering

Comments